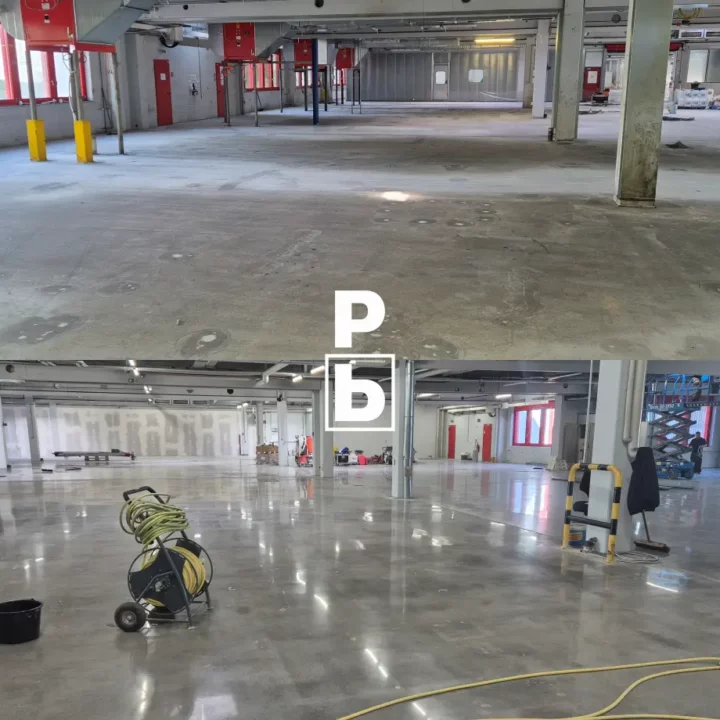

Industrial flooring renovation

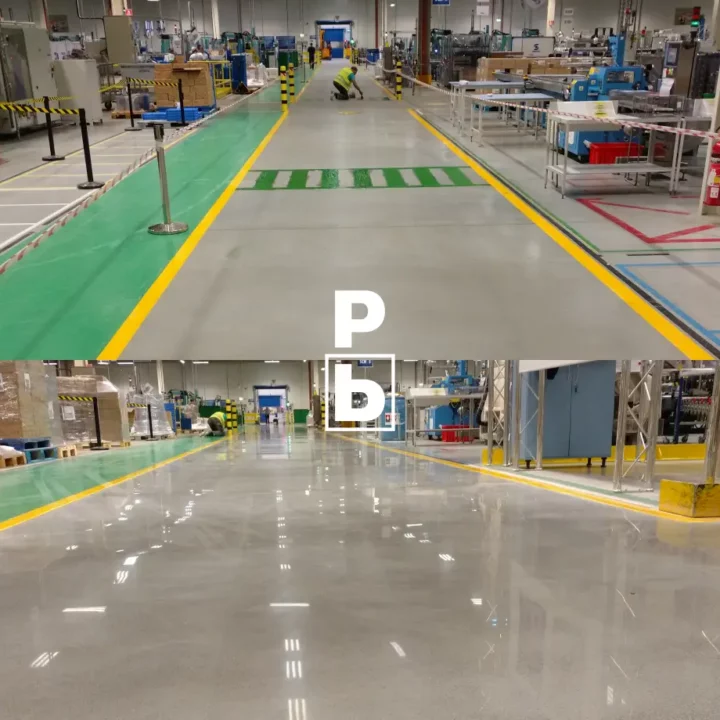

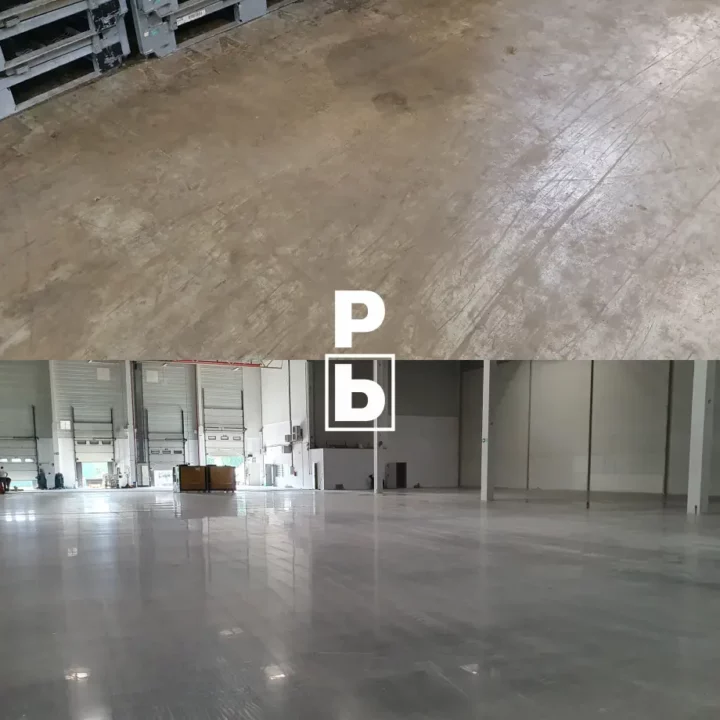

Industrial floors are a significant investment and are expected to last for many years. Throughout their service life, they are exposed to moving loads, chemicals, and damage. When their condition hinders everyday use, spoils the room’s appearance, or poses a threat to employees and customers, renovating the floor becomes the most economical solution.

Polished concrete contractor

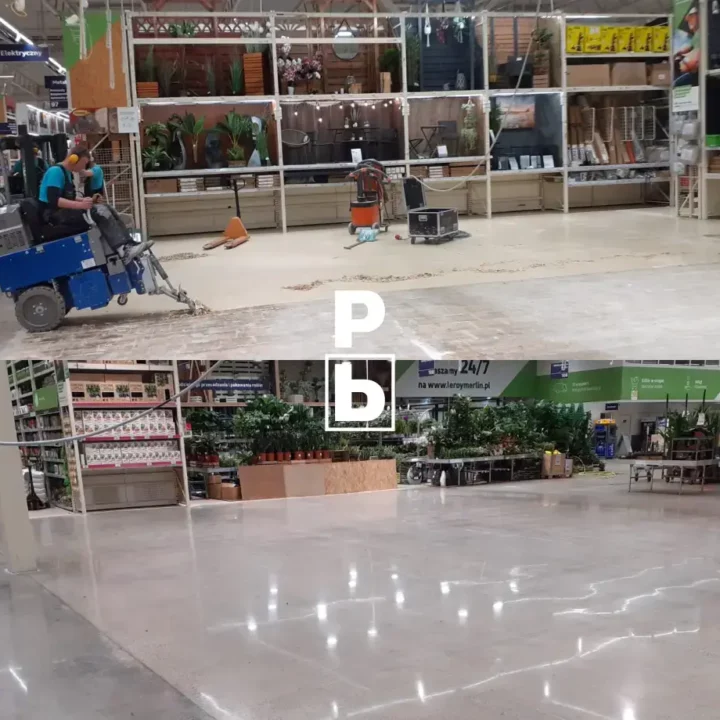

We specialize in the renovation of industrial concrete floors using high-performance planetary grinders. We provide high-quality concrete polishing services for industrial floors in Poland and Europe. Our services are suitable for both worn floors requiring renovation and new floors requiring a functional, durable finish.

Industrial and commercial concrete polishing in floor renovation

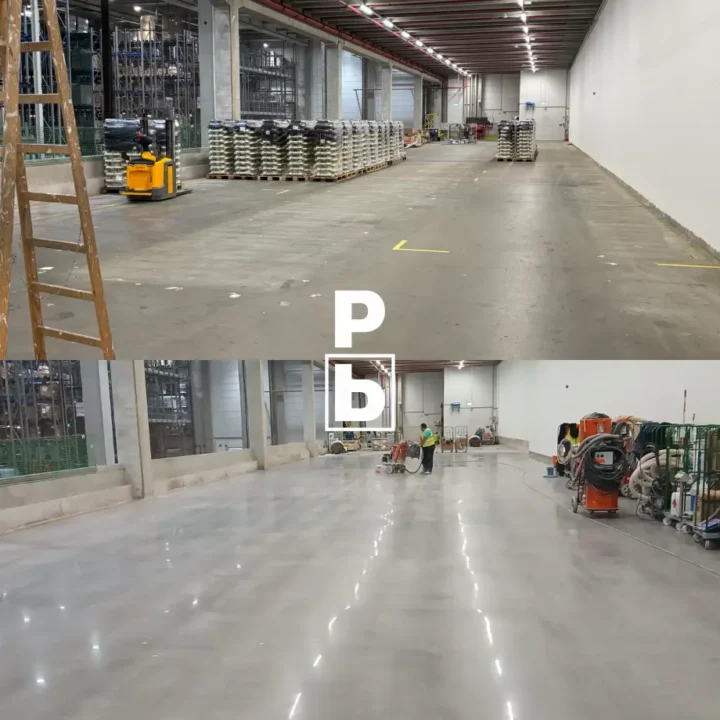

Our renovation services include the regeneration of heavily damaged surfaces. Polishing concrete with planetary grinders is cheaper, less invasive, and more environmentally friendly than removing the old floor and pouring a new concrete one. We use different techniques depending on the identified causes and expected results. Below is a comprehensive guide describing our floor renovation process using the NORTEC® concrete polishing method.

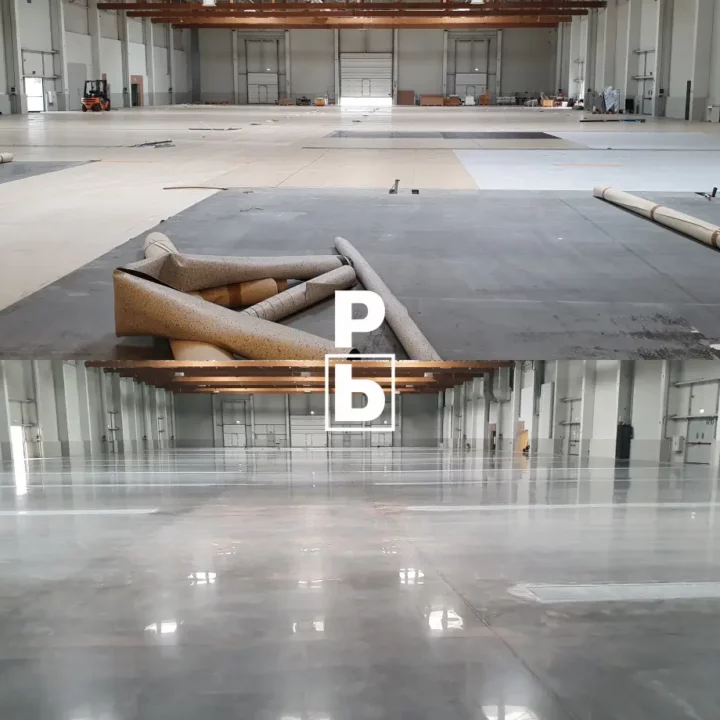

STEP 1. SURFACE PREPARATION – REMOVING COVERINGS

Comprehensive renovation of industrial floors begins with proper preparation of the substrate. First, we remove all existing floor coverings, such as linoleum, vinyl tiles, ceramics, and terrazzo tiles. When removing old and damaged industrial floor coverings, our goal is to avoid damaging the concrete layer underneath. We have self-propelled heavy equipment as well as small, push-type floor removal machines at our disposal.

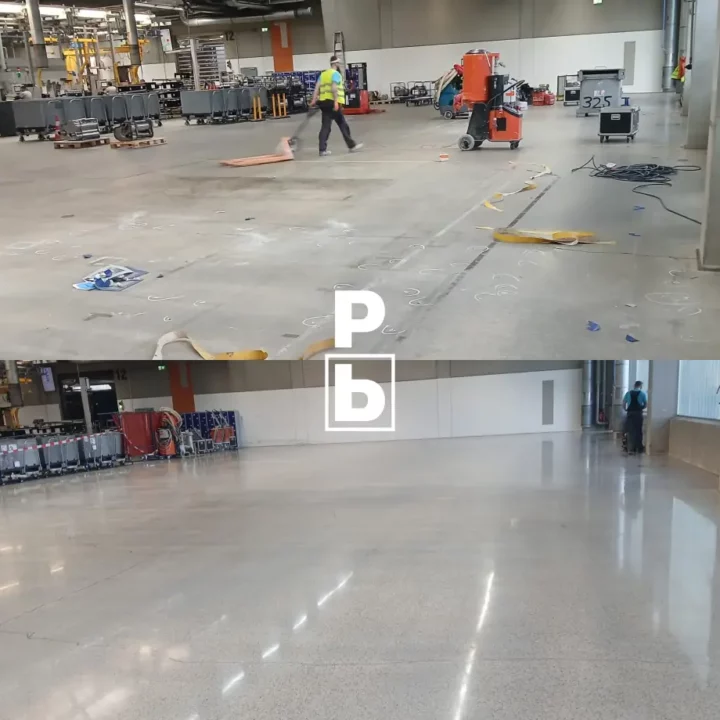

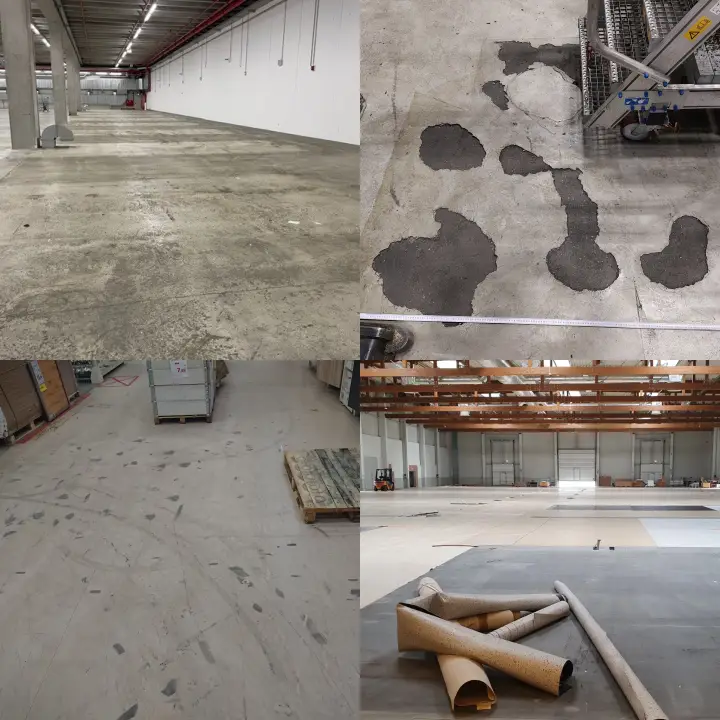

STEP 1. SURFACE PREPARATION – FLOOR GRINDING

If industrial floors are not covered with cladding, we start by using powerful planetary grinders. Our professional equipment effectively removes adhesives, thin coatings, paints, and resin impregnation residues. Our fleet of concrete processing machines can handle large surfaces as well as walls and columns. We know how to choose the right diamond tools so as not to damage the concrete substrate. Powerful industrial vacuum cleaners allow us to grind concrete in enclosed spaces without creating dust.

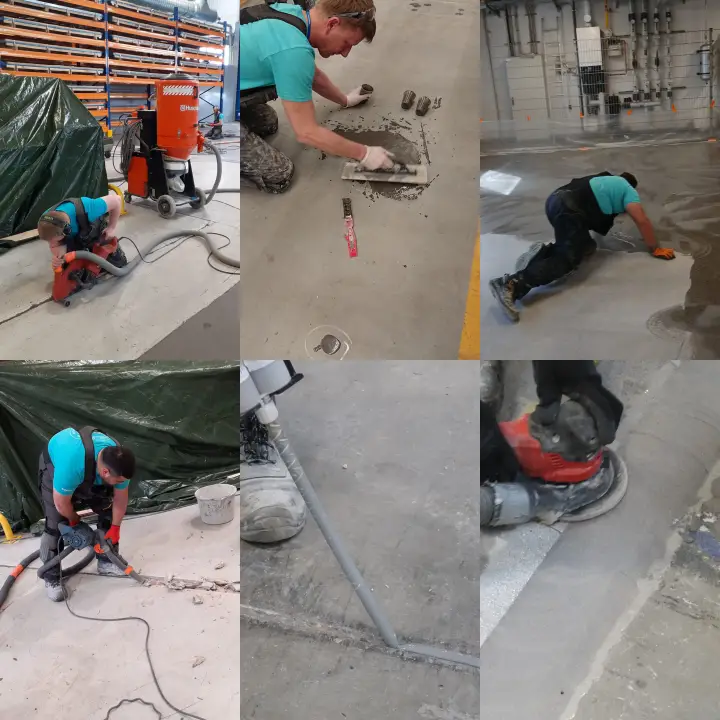

STEP 2. CONCRETE REPAIR – Repairing floor damage

After cleaning and leveling the substrate, we repair any damage or defects in the floor. Standard industrial floor repairs include removing cracks and minor or major damage to concrete, driving in rack anchors, filling holes with resin, rebuilding expansion joint edges, and replacing expansion joint fillings. We use fast-setting repair materials that guarantee excellent adhesion to the substrate. The repair methods and products used depend mainly on the floor finish chosen by the customer.

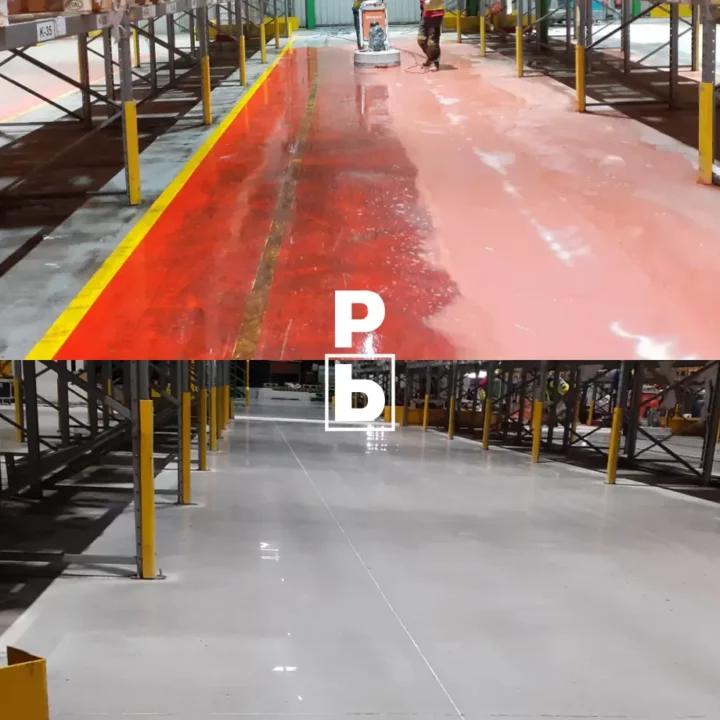

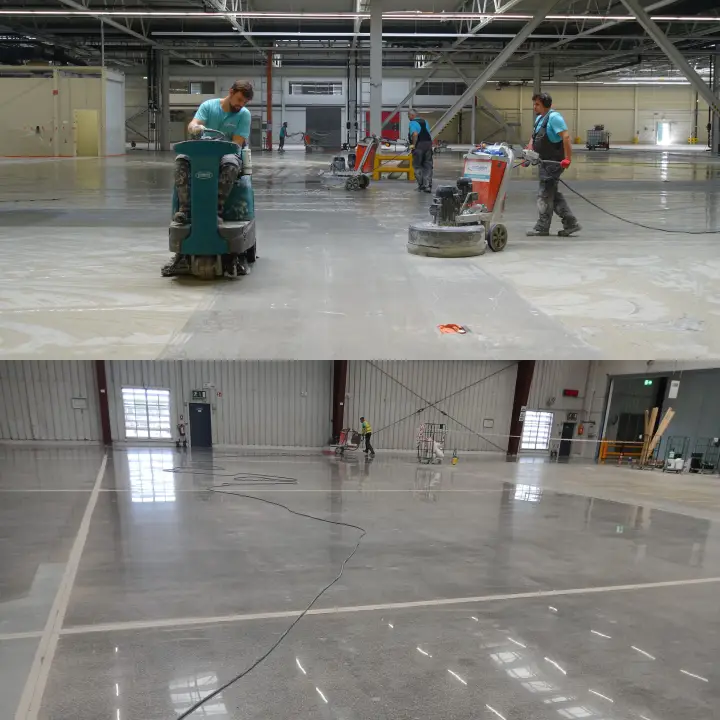

STEP 3. CONCRETE FINISHING – smoothing, impregnation, polishing

We have been passionately creating polished concrete since 2006. In a nutshell, polishing concrete with planetary grinders involves changing the surface of a concrete floor to achieve a specific level of smoothness (roughness). An indirect effect of concrete polishing is the exposure of aggregate in the floor and the creation of a glossy surface. In addition, to increase the protection of the polished concrete surface against the penetration of liquids and dirt, we use specialized NORTEC® mineral impregnants during and at the end of the polishing work. The main advantages of our concrete polishing technology are the absence of dust during work, flexible repair planning, and the possibility of immediate use of the floor after completion of the work.

polishing concrete floors in new commercial and industrial facilities

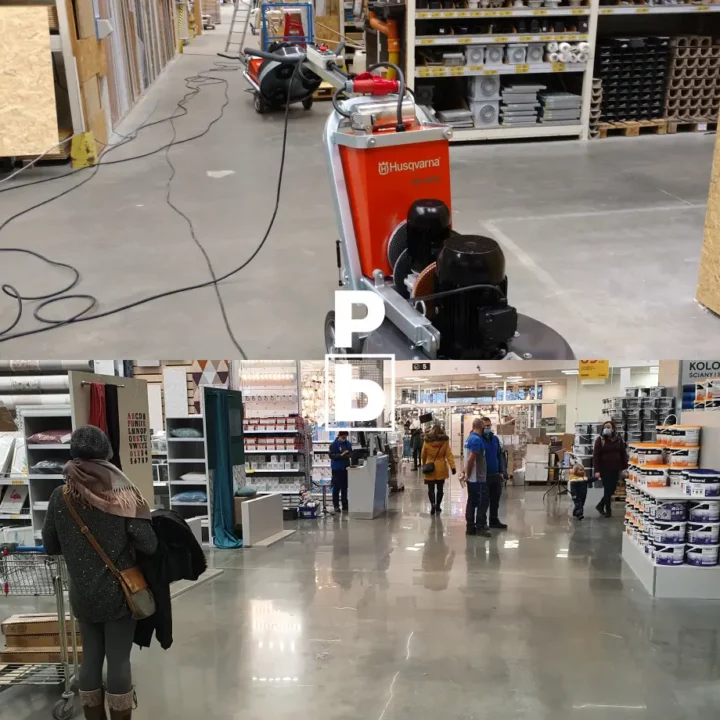

Polished concrete floors

Customers for whom we have polished concrete during floor renovation often decide to polish new industrial floors. Our technology not only provides a more aesthetic, functional, and durable finish, but also eliminates the risk of hidden surface defects resulting from construction errors during the installation of concrete floors. By polishing new concrete floors, we remove the weakest layer of the floor and perfectly protect the concrete against dusting, liquid penetration, and dirt. We provide a high-quality finish that is easy to maintain, highly resistant to abrasion, attractive to customers, and meets the needs of employees.

Why choose a polished concrete finish?

- Dust-free and abrasion-resistant concrete floors

- Surfaces with an aesthetic shine

- Easy to maintain

- Slip-resistant and free from synthetic materials

- Cleaner goods and a pleasant indoor climate

- Very short floor renovation time.