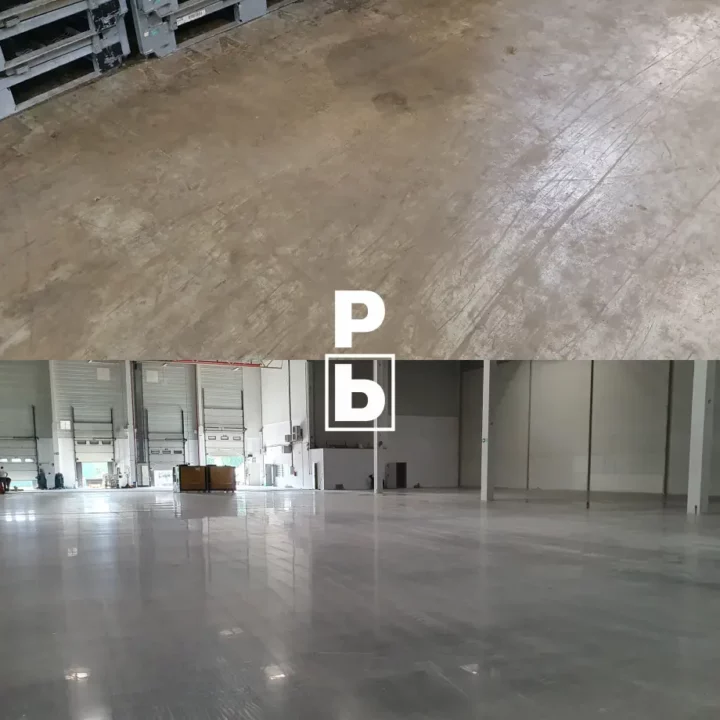

Industrial flooring renovation

An industrial floor is a significant investment, designed to last for many years. Therefore, when its condition hinders everyday use, spoils the appearance of the space, or endangers employees and customers, renovation is the most economical solution. Our renovation services include modernizing or replacing heavily damaged surfaces. These services are cheaper, less invasive, and more environmentally friendly than removing the old floor and installing a new concrete one. We use different techniques depending on the causes identified and the expected results.

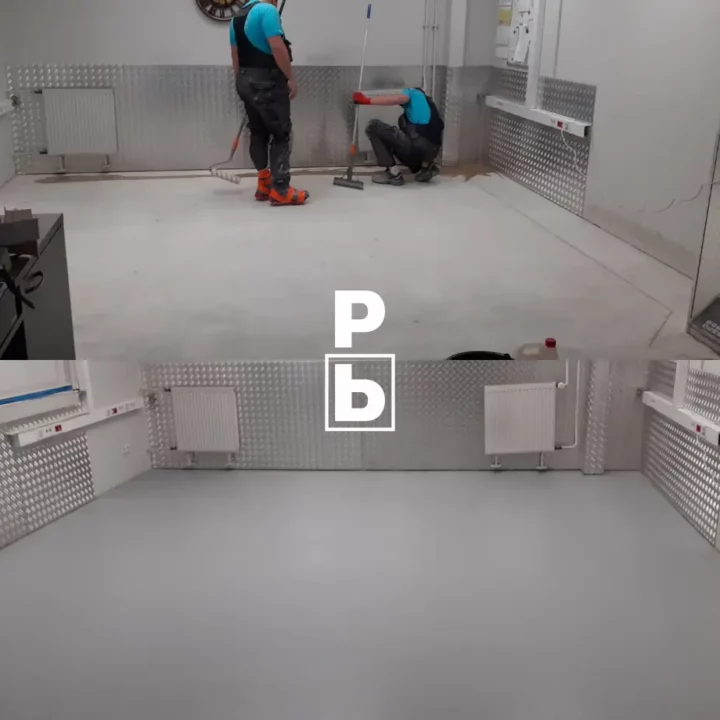

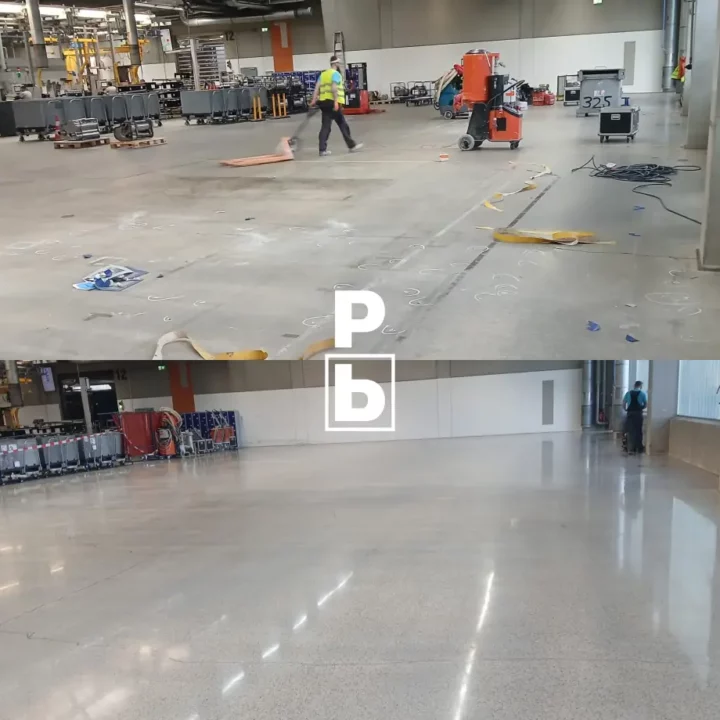

FLOOR COATING REMOVAL

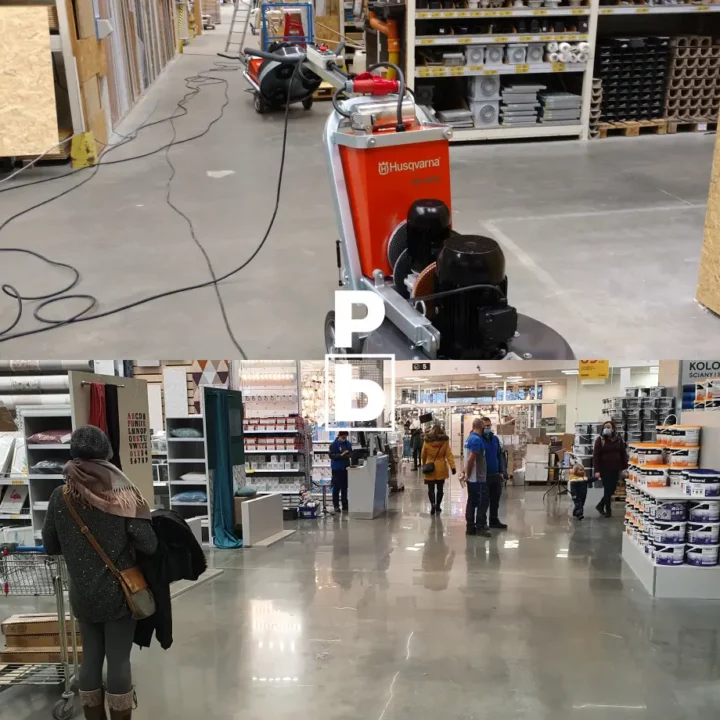

Every comprehensive industrial floor renovation begins with proper substrate preparation. First, we remove all existing floor coverings, adhesives, and impregnating resins. Then, we level the concrete surface using planetary grinders. Our professional-grade equipment enables us to remove floor coatings from large areas and small rooms alike. Our powerful industrial vacuum cleaners enable us to grind concrete on busy floors without creating dust.

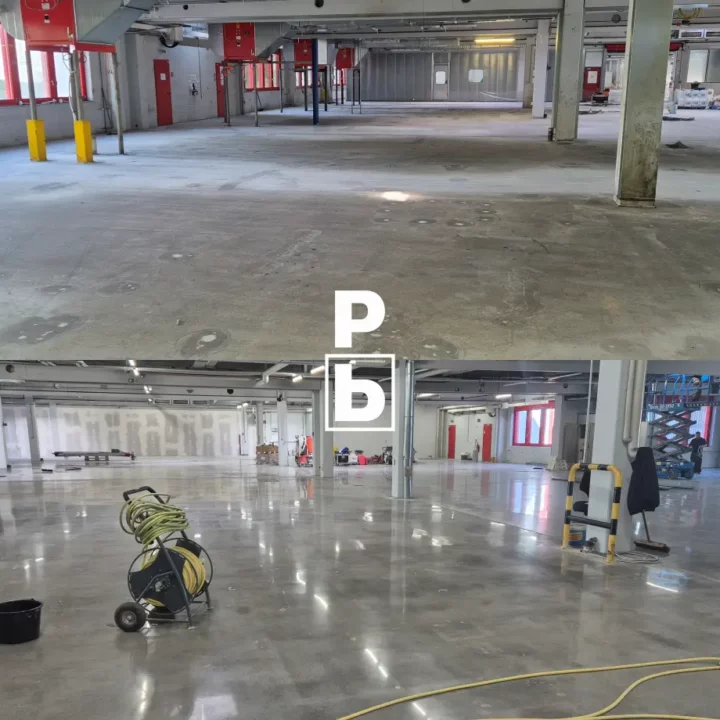

Repairing Floor Defects

After cleaning and leveling the substrate, we repair any damage or defects in the floor. Standard industrial floor repairs include filling in cracks, repairing minor or major concrete damage, hammering cinch bolts, filling holes with lowviscosity resins, rebuilding arris of sawcut joints, and replacing contraction joint fillings. We use fast-setting repair materials that guarantee excellent adhesion to the substrate. The repair methods and products used depend mainly on the floor finish chosen by the customers.

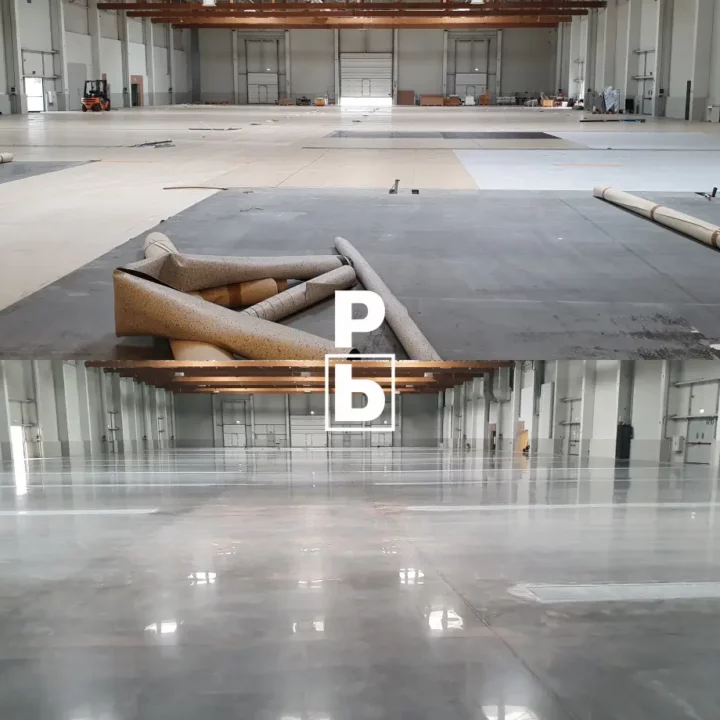

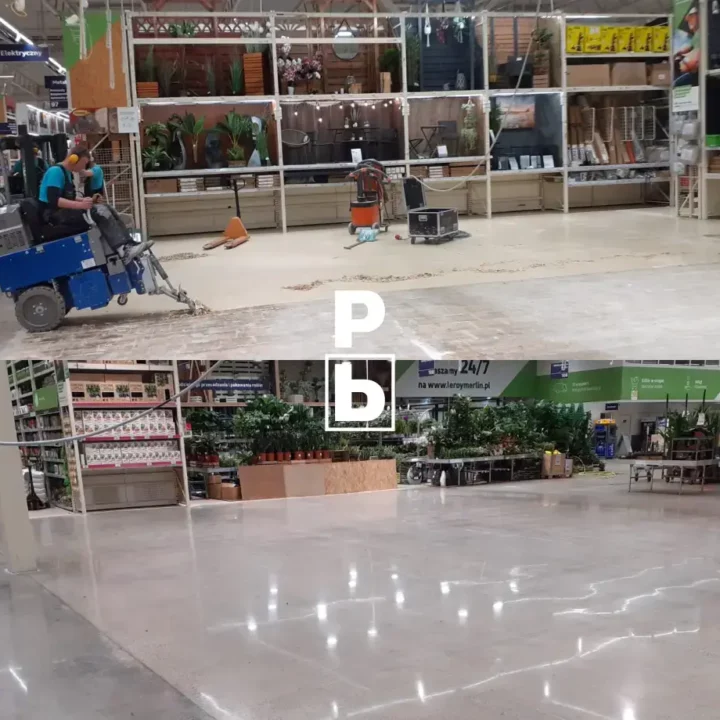

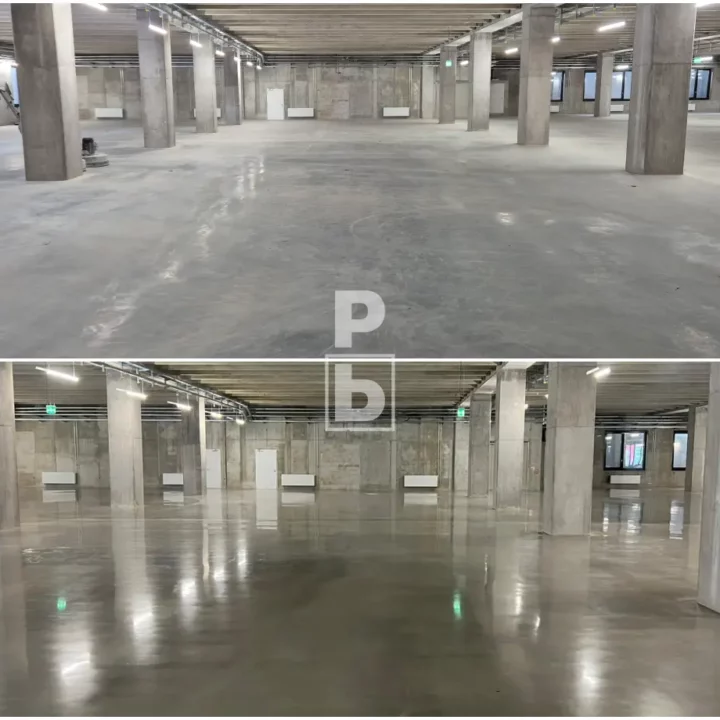

Polished Concrete Floor Finish

We have been delivering polished concrete floors since 2006. In short, polishing concrete with planetary grinders changes the surface of a concrete floor to achieve a desired level of smoothness. An indirect effect of polishing concrete is exposing the aggregate in the floor and a desired level of gloss. To increase protection against liquids and dirt penetration, we use specialized reactive sealers during and at the end of the polishing process.

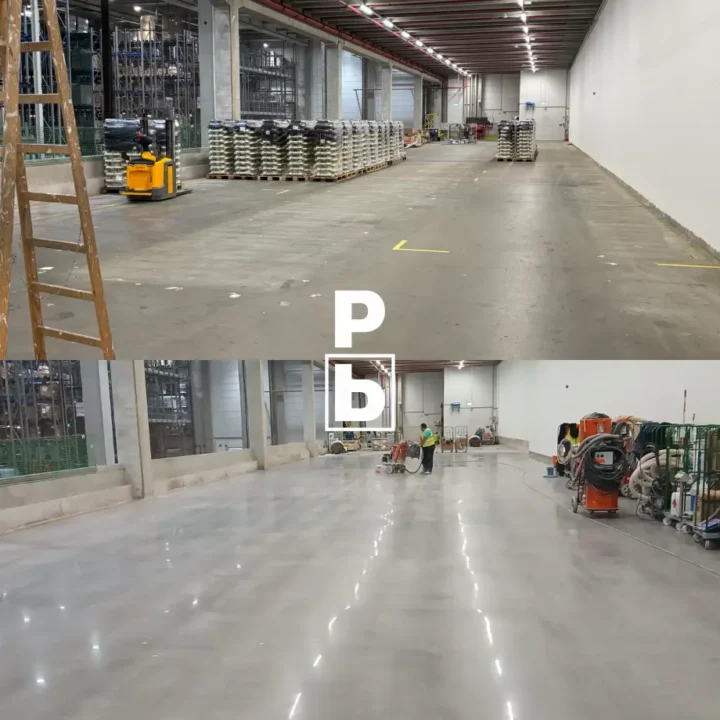

NORTEC® System

We recommend using NORTEC® technology for concrete polishing to regenerate worn concrete floors. This process is ideal for areas with heavy foot and forklift traffic. We perform concrete polishing in large stores, warehouses, distribution centers, and exhibition halls. The main advantages of our technology are the absence of dust during the process, flexible repair scheduling, and the ability to use the floor immediately after completion. Our high-quality finish is easy to maintain, highly resistant to abrasion, and attractive to customers. It also meets the needs of employees.

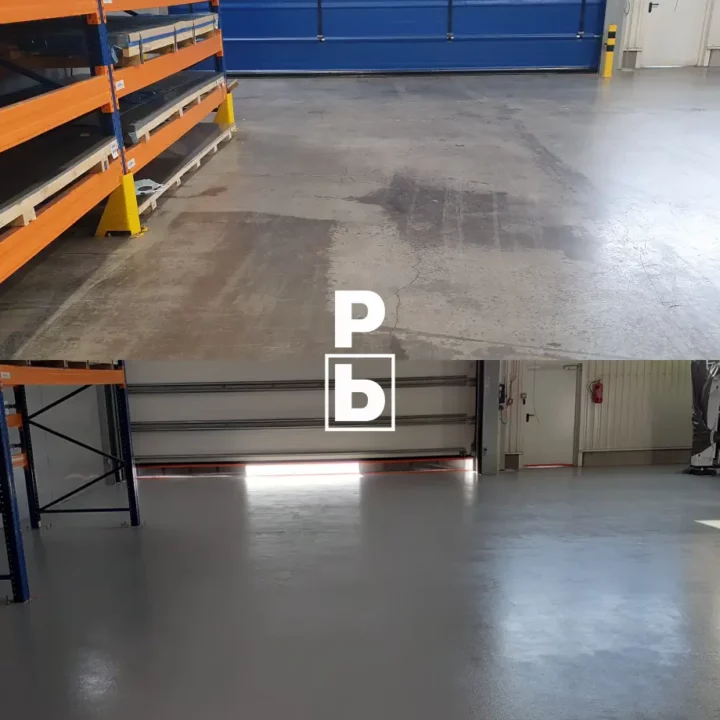

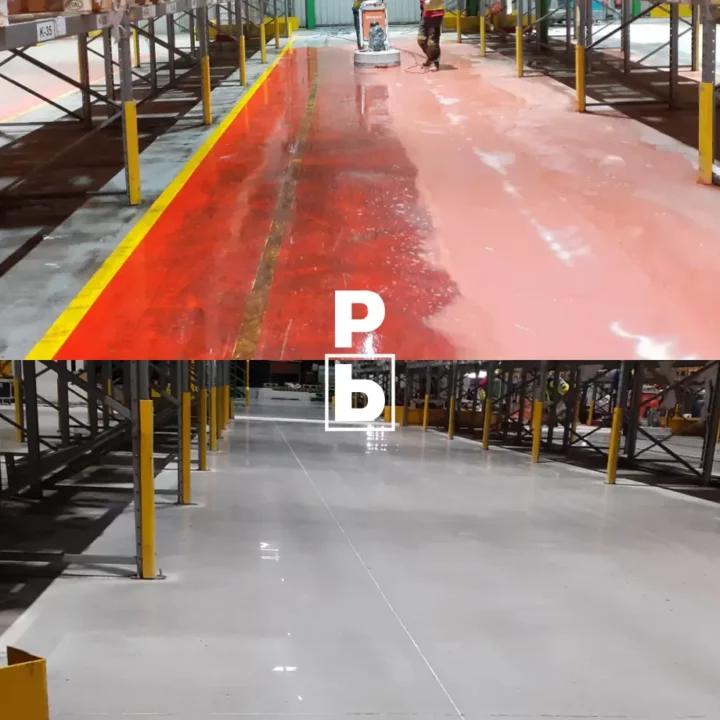

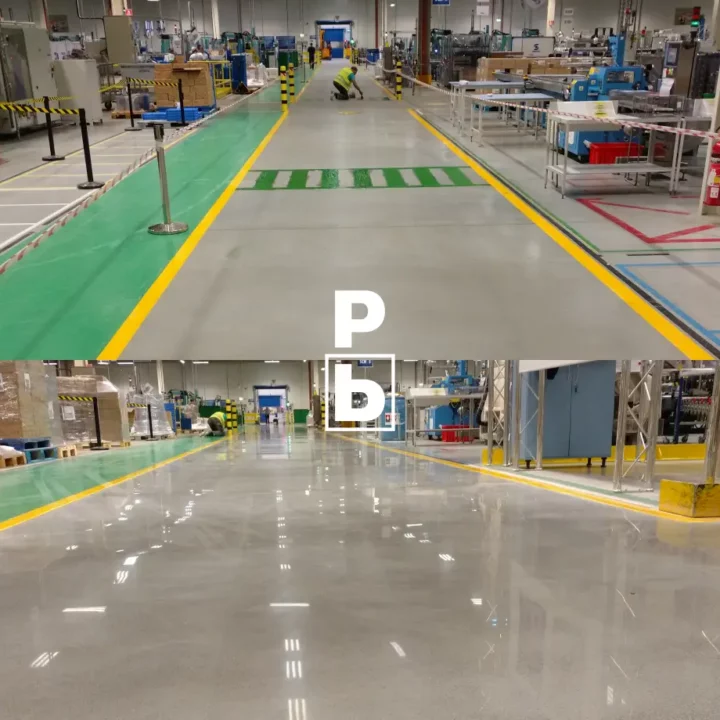

Resin coatings

Floor coatings are the ideal solution wherever increased protection against chemicals, a uniform color, or resistance to heat is required. For industrial floors, the speed of finishing work is also important. Every day of downtime means a loss for the entrepreneur. Unfortunately, conventional polyurethane and epoxy resin-based floor coatings have a long curing time and can only be used at temperatures between 8°C and 30°C. Conversely, fast-setting MMA coatings typically have poor adhesion to the substrate and emit an unpleasant odor during application.

MC-Floor TopSpeed System

MC-Floor TopSpeed is a high-performance system that enables reliable and efficient finishing work in extreme temperatures and high humidity. An entire industrial floor can be completely modernized in just a few hours. Full curing takes place after 48 hours. The result is an extremely durable surface that is highly resistant to various chemicals and cleaning agents.

What sets our services apart

- quick floor renovation

- competent service teams

- dust-free work

- experience in planning and project execution

- expertise in repairing and protecting concrete

- professional grinding and measuring equipment

- short lead time

- post-construction service